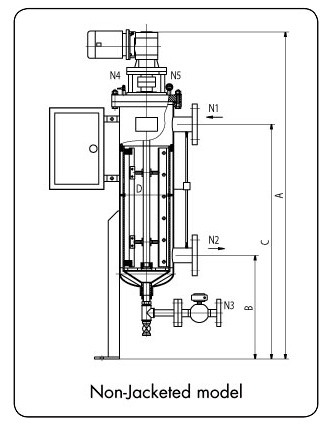

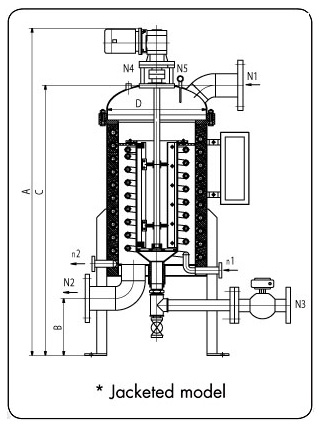

| Model No. | A (inch) | B (inch) | C (inch) | D (inch) | Inlet/Outlet Connection | Drain Outlet Connection | Max Flow Rate (US GPM) |

|---|---|---|---|---|---|---|---|

| SAB-ICM273 | 62.2 | 25.6 | 46.1 | 10.7 | 2” | 2” | 70 |

| SAB-ICM350 | 66.9 | 25.6 | 46.1 | 13.8 | 3” | 2” | 180 |

| SAB-ICMJ350 | 66.9 | 11.8 | 46.9 | 13.8 | 2” | 2” | 130 |

| SAB-ICMJ450 | 68.9 | 11.8 | 48.0 | 17.7 | 3” | 2” | 220 |

ICM Automatic Filters come standard with wedge wire screen baskets

ICM Automatic Filters come standard with wedge wire screen baskets

Automatic Scraper Self-Cleaning Filter Systems– ICM Series

This automatic filter system is used to filter high-viscosity fluids with high solids content and fibrous impurities. The automatic filter system consists of a main housing, gear motor, filter screen, electric brush self-cleaning system, an electrically controlled drain valve and a logic control system.

I. PROCESS

The process begins with fluid flowing through the inlet. The fluid flows from the inside of the screen to the outside. As the fluid flows through the screen, solid impurities that are larger in size than the screen’s micron rating become trapped on the inside of the screen. The filtered fluid exits the system through the outlet. As the impurities build-up on the inside of the screen, a pressure differential is created, and will continue to increase between the contaminated and clean sides.

II. CLEANING CYCLE:

- The ICM automatic filter system’s design utilizes a logic control system. The end-user only has to enter the max impurities content.

- The control system automatically determines the pressure drop value at which the system starts the automatic cleaning cycle.

- The end-user also has the option to manually enter the pressure drop value, however this is normally only used for commissioning purposes. It is not recommended to operate the automatic filter as such. The automatic filter should be operated as explained in items #1 and #2 above.

- The control system automatically adjusts this pressure drop value accordingly, if there are changes in impurities content, viscosity, etc., in order to optimize filtration and drainage.

- Once the pressure drop value has been reached (i.e. pressure dependent setting), the control system sends a signal to automatically start the gear motor.

- The gear motor drives the electric brush system for a pre-set length of time which removes the impurities on the inside of the screen, thus allowing the automatic filter system to continuously operate.

- The control system further monitors the level of impurities in the collection chamber.

- At a pre-set value, the control system automatically opens the drain valve and the impurities are flushed out of the system.

- The automatic filter system’s pressure then returns to its normal operating level.

- The control system can also initiate a cleaning cycle at pre-defined time intervals (i.e. time dependent setting), but pressure dependent settings take precedence.

Design Advantages and Features:

- Automatic online continuous filtration – the automatic filter system does not have to be taken offline to enter the cleaning mode, or to collect and drain impurities, thus enhancing the end-user’s profitability and overall productivity.

- Rotating scraper / brush cleaning system.

- A gear motor is used to drive the automatic filter system. The electric brush system automatically removes the impurities from the filter screen in a timely manner as to avoid any filter screen change-outs, to maintain a constant filtration process and to ensure a clean filter screen.

- The logic control system automatically adjusts cleaning / drainage settings according to changes in fluid parameters. Through a standard USB interface, the end-user can connect an external keyboard and mouse to adjust parameters.

- Control panel display – color display; inlet / outlet pressure indication; graphical representation of pressure drop curve; filter on-line indication.

- The stainless steel wedge-wire filter screen provides excellent filtration and sustains much more wear and tear.

- In many cases, the ICM automatic filter system has replaced traditional bag filter, screen filter, frame filter and other filter systems.

- The ICM automatic filter system is most suitable for viscoelastic liquids (ie. viscosity less than 5000 CPs)

Applications:

- Coatings

- Resins

- Food industry

- Pulp & Paper industry

- Chemicals

- Water treatment